Contact person: Li Yan

Tel: 13478023966

Contact person: Gao Tianyu

Telephone 18241295123

Contact person: Ran Entong

Tel: 18804233223

Contact person: Wang Haichuan

Tel: 13591588822

Contact person: Zhang Guobin

Tel: 13104229487

Contact person: Zhang Guoqiang

Tel: 1394 1205541

Website: en.lntalc.com

Address: Wangjiakan Village, Bali Town, Haicheng City, Liaoning Province, China

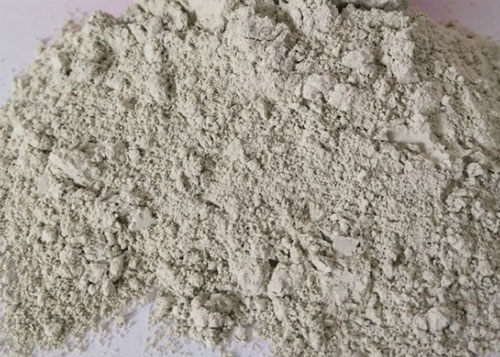

Ultrafine grinding technology is an important means of deep processing of non-metallic ore. The results show that the ultrafine grinding process is not only a simple reduction of particle size of materials, but also accompanied by many complex changes in physical and chemical properties and crystal structure of powders. Through relevant experimental research, some good researchers of Liaoning talc powder found that the mechanochemical changes of talc powder during ultra-fine comminution mainly include the following points. The research results provide a new idea for the development of mechanochemical deep processing technology of non-metallic ore and the mechanochemical theory of ultra-fine comminution.

First, the change of surface properties during ultrafine grinding. Surface property is the most important index to measure the application effect of ultrafine powder. After ultrafine powder, the particle size of talc powder is refined continuously. The surface property of refined talc powder is more active and its surface activity is stronger. When used as ceramic raw material, the dispersion and sintering properties of ultrafine talc powder in matrix are better.

Secondly, the change of crystal structure during ultrafine comminution. The degree of crystallization of talc powder decreases with the progress of ultrafine grinding.

Thirdly, the change of chemical bonding during ultrafine grinding. In the process of ultra-fine comminution, the effect of mechanical force excludes - OH in talc powder, the formation of hydrogen peroxide increases, the Si-O bond gradually breaks, the ordered structure is destroyed and the lattice changes occur.

Fourthly, the change of crystal bond energy during ultrafine comminution. In the process of ultra-fine comminution, the specific surface area of talc powder increases continuously, so with the continuous process of ultra-fine comminution, its crystal bond energy becomes smaller and smaller, and bond breakage will occur, which is also the main reason for the mechanochemical change of talc powder.